The Pivotal Role of Landfill / Biogas Dryers in Revolutionizing Waste Processing

Posted by AVP on Apr 10th 2024

Available 24/7 – Call and setup an account with us to order by P.O.

Compressed air leaves the compressor hot, wet, and dirty. In order to be useful as a source of power, it must be cooled, filtered, and dried. There are different types of compressed air dryers available.

AVP can help you find the best one depending on your application and specific moisture requirement.

We also provide a complete line of:

Compressed air – also known as industry’s Fourth Utility – is a vital energy source for the operation of almost every industry in the world. Unlike electric, water, and natural gas utilities, the user generates their own compressed air, usually on site. Compressed air is used in applications as small as laboratories, to as large as major manufacturing plants like oil refineries, and everything in between.

For OEM, laboratory, and instrument applications when a vibration and noise free air source is a priority, AVP supplies high-quality Panther Silent compressors, with noise levels as slow as 30 dB/A. These are also available as oil-free units. For larger flow requirements, we have “quiet” high-efficiency rotary screw compressors from FIAC. These compressors integrate the latest technology and are available as base-mount, tank mounted, and with integrated refrigerated air dryer.

We also provide a complete line of:

The purpose of natural gas dehydration units (also called natural gas dehydrators) is to remove water from natural gas and natural gas liquids. When produced from a reservoir, natural gas usually contains a large amount of water and is typically completely saturated or at the water dew point.

This water can cause several problems for downstream processes and equipment. At low temperatures, the water can either freeze in piping or as is more commonly the case, form hydrates with CO2 and hydrocarbons (mainly methane hydrates). Depending on composition, these hydrates can form at relatively high temperatures plugging equipment and piping. (Source: Wikipedia).

AVP also supplies filters and desiccants for natural gas dryers as well as a single-tower pipeline dryer for drying landfill and digester gas.

We also provide a complete line of:

Many compressed air applications require the equipment to be transported to jobsites or remote locations. AVP has a variety of types of portable compressed air dryer systems. These systems are ideal for rental fleets, plant air system back-up, mobile abrasive blasting and painting, pipeline dehydration, and many others. These systems utilize single-tower deliquescent dryers, regenerative desiccant dryers, air-cooled aftercoolers, and filtration for cool, clean, dry compressed air.

We also provide a complete line of:

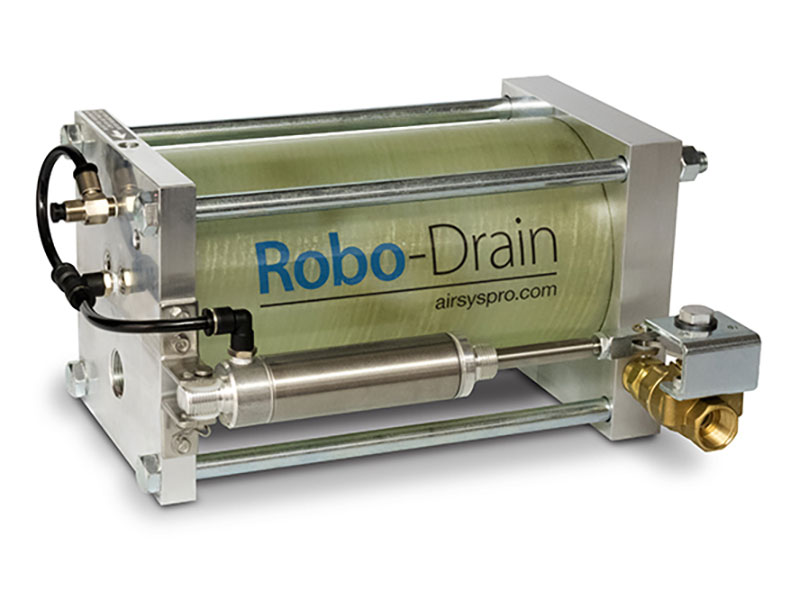

AVP has a variety of accessories to help you keep your compressed air or natural gas systems clean and dryer. All types of desiccants for compressed air dryers and natural gas dryers. Several types of automatic drain valves for eliminating condensation from compressed air lines, including timed solenoid valves, timed rotary ball valve, and pneumatic demand drain valves. We have all types of filters for compressed air and natural gas. We have several different types of dew point meters, loop-powered, in-line, and portable, available for use in compressed air and natural gas. And since air from a compressor can be quite hot, we have air-cooled and water-cooled aftercoolers.

We also provide a complete line of:

Compressing and then cooling air produces large quantities of liquid condensate as well as compressor oil which must be drained from the system. We offer a variety of automatic drains to remove condensed liquid – usually a mixture of water and compressor lubricant — from compressed air systems. Our drain valves are commonly installed on air receiver tanks, drip legs, bulk moisture separators, coalescing filters, refrigerated air dryers, and deliquescent air dryers.

Shop Collection

Posted by AVP on Apr 10th 2024

Posted by AVP on Apr 10th 2024

Posted by AVP on Apr 9th 2024