Blast Pak for Painting and Blasting Applications

The Blast Pak is a single tower deliquescent drying package with conveniently integrated peripherals that are pre-assembled and welded to a forklift skid, allowing maximum portability for mobile drying applications. These systems can be easily lifted on the back of a truck or trailer and moved about within a plant or worksite.

The Blast Pak is an ideal solution for mobile blasting contractors. Wet compressed air clogs blasting pots and compromises the quality of the blasted substrate by putting moisture back on the surface. This moisture then flashes to rust, necessitating costly re-work.

With an integrated aftercooler, the Blast Pak first cools hot and wet air discharged from the compressor. Cooling forces a substantial quantity of entrained moisture to condense. But even after exiting the aftercooler, the air is still saturated with vapor (100% relative humidity). Next the compressed air passes through the drying vessel, which contains a specially formulated Van Air desiccant called Dry-O-Lite. This desiccant cuts the humidity of the air roughly in half. Finally, air flows through an after-filter to trap any fine particulate matter suspended in the air flow.

The blasting contractor is left with cool, clean and dry compressed air for superior blasting quality and zero downtime.

Blasting contractors: remember that an aftercooler and moisture separator alone do not prevent condensation from occurring downstream. To lower the humidity of blasting air, and prevent condensation from occurring on the blasted surface, a dryer must be used. Dry air is the key to superior surface preparation.

- Features & Benefits

- Applications

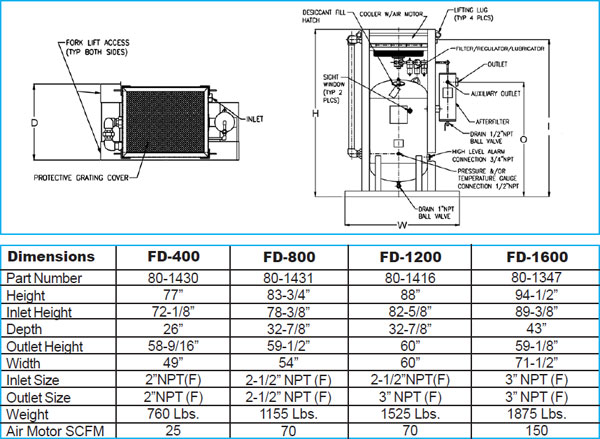

- Dimensions

- Brochure

- Models match common portable compressors sizes: 250, 400, 800, 1200 and 1600 scfm

- Initial fill of Dry-O-Lite included

- Steel skid forklift channels and lifting lugs for portability

- Air motor with filter, regulator, lubricator and muffler

- Optional 12V DC motor for 250 cfm model

- Epoxy internal dryer coating for long vessel life

- Optional zero-loss pneumatic drain

- Downstream particulate filter with permanent stainless steel media

- Two dryer-sight windows for desiccant level viewing

- Mobile abrasive blasting

- Mobile paint spraying

- Rail yards

- Equipment rental fleets