ASP ACCU Series Oil/Water Separators for Condensate Management

Designed to simultaneously process different types of oil with the use of propriety media. Capable of 24 hour continuous operation. No electricity required and no moving parts. For compressed air systems of 50 to 2,400 SCFM

The ASP ACCU Series Oil/Water Separator is the simplest, most economically viable, method of reducing the volume of compressed air condensate destined for disposal. Depending on air intake conditions, water represents up to 98% of the total condensate load you are forced to deal with. So, it stands to reason – you can reduce your waste hauling costs by up to 98% if you can effectively remove the water!

The ACCU Series provides an environment where the small percentage of an insoluble lubricant can rise to the surface to be skimmed off. Water that is displaced by fresh incoming condensate slowly sinks to the bottom, then rises to pass through our unique polar Pre-absorber before finally being purified by either activated carbon (ACCU-SEP) or zeolite (ACCU-ZORB.) From there, the clean water can be safely discharged to your sanitary sewer system.

Lubricants that possess a specific gravity less than that of water tend to be ideal candidates for the ACCU-SEP system due their tendency to separate. Conversely, soluble lubricants such as ATF, Detergent based Motor Oils and, Polyglycol based coolants do not separate well from water. For these problematic lubricants, the filter media of the ACCU-ZORB unit does the majority of the work separating the lubricant from the water and have to be replaced frequently.

If you have any doubt about your system’s requirements, before using this product we recommend a simple glass jar test. First, collect a sample of the actual compressed air condensate in a clean, clear glass jar (mayo, jelly, etc.). Shake it well, then set it down to allow it to separate. Time how long it takes to separate (it could take minutes or even hours depending on the lubricant). Lubricants that separate easily will settle to be relatively clear water for most of the sample, with a little oil on the surface, and can be used

with the ACCU-SEP systems. If you see milky looking emulsified oil after allowing

the sample to rest, an ACCU-ZORB system is likely a better choice.

Please contact AVP if you have any questions.

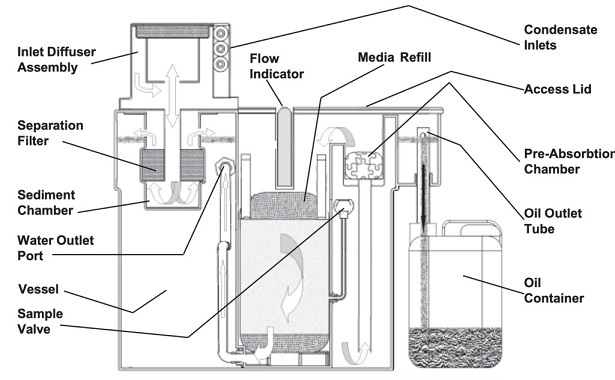

Here’s How It Works

Depressurization:

Condensate is depressurized as it enters the separator through the (3) ½” Condensate Inlets in the Inlet Diffuser Assembly. Air is exhausted to atmosphere through the Filter located in the top. Gravity draws the new condensate into the Sediment Chamber and pushes the old condensate through the Separation Filter. The Separation Filter causes fine oil droplets to coalesce which speeds up the separation process. It also prevents the dirt, rust and scale from leaving the Sediment Chamber.

Processing:

Both the Oil and Water enter the Vessel through exit holes in the Sediment Chamber. Nonsoluble oil will float to the surface and then be removed via the Oil Outlet Tube to the Oil Container The Water slowly sinks to the bottom of the Vessel. It rises through a tube and enters the Pre-Absorption Chamber where it is pre-cleaned before it flows down through the Media Refill for final polishing. From there it exits the separator via the Water Outlet Port located conveniently at the back of the vessel.

Monitoring:

The ACCU-Series was designed with the user in mind. A translucent Oil Container is provided so you can easily tell with a quick glance, just how much oil has collected for disposal. Our LEVEL MINDER option offers you a remote Alarm System to warn you that the oil container is full and needs to be changed.

Sample Jars are provided to collect water from the Sample Valve. A simple comparison test will confirm when it’s time to change the Media Refill. The enclosed Maintenance Log will help you document your sampling results, providing you with evidence of compliance with local sanitary sewer regulations.

Our exclusive Flow Indicator pops-up and then stays up, to provide you with a visual indication that a reduced flow condition has occurred during operation. Designing it so that it stays up allows it to advise you that under peak operating conditions you are no longer getting full flow. This provides you with time to respond before it fails completely like other brands do. An easily removable Access Lid makes removal of the filter media quick and easy.

When you can’t be there to see it, we offer our exclusive Remote Flow Indicator option. It provides you with both the visual indication of our Flow Indicator and the added benefit of a set of remote alarm contacts. If a reduced flow condition occurs, the contacts close to actuate whatever device you choose to sound the alarm. Nobody else offers you this kind of security at any price.