Equipment failure, corrosion, frozen airlines, and other operational concerns are usually caused by water vapor in compressed air systems in heavy-duty industrial operations. The moisture in compressed air is removed using a desiccant air dryer. These systems may be found in every industrial application that requires dependable equipment and superior quality control. Regenerative desiccant dryers, on the other hand, can provide the air quality that many facilities demand. Sadly, too many times, the choice to acquire a regenerative dryer is based only on the initial capital expense. Because AVP can provide you with low-cost mini air dryers, your air system will be able to operate at its peak efficiency without any issues. You can rely on PUREGAS Regenerative Desiccant Air Dryers to remove moisture from the compressed air stream in a pinch so request a quote today.

PUREGAS Regenerative Desiccant Air Dryers

PUREGAS manufacturers heatless regenerative miniature air dryers using pressure swing adsorption (PSA) technology. These mini air dryers are designed to provide trouble free dry air to maximize the effectiveness your air system. If it is for your point of use or an original equipment manufacturer, we can supply units for -40°F or -100°F dewpoint outputs.

Some Typical Dry Compressed Air Applications:

- Ozone Generators

- Environmental Chambers

- Pneumatic Automation Systems

- Medical Air Compressors

- Dental Air Compressors

- Bus Door & Locking Systems

- CEMS Systems

- FTIR Spectrometers

- NMR Spectrometer

- Laboratory Analyzers

- Dry Sprinkler Systems

- Outdoor HVAC Controls

- Electronic Chip Testing

- Dry Nitrogen Replacement

- Air Bearings

- Vortex Tubes

- Antenna Pressurization

- Waveguide Drying

- Air Brushing

- Gas Chromatographs

- Robotic Machinery

- Car Wash Controls

- Graphic Printers

- Air Turbines

- Air Operated Pumps

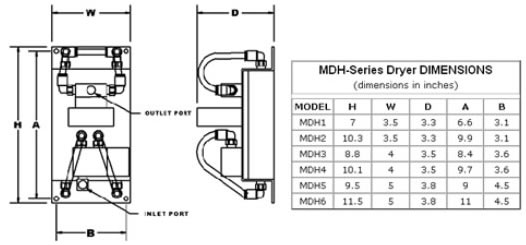

MDH-Series Miniature Desiccant Air Dryers capacity from 0.1 to 3.2 SCFM

The MDH mini air dryers can be used with fractional horsepower compressors. The MDH heatless air dryer can produce reliable, low dewpoints, and only take up a small amount of space. With its small footprint, it can be placed inside equipment cabinets for original equipment manufacturers (OEM’s) or at a point of use in your production facilities.

- Features

- Specifications

- Dimensions

- Brochure

- Very dry outlet air to -100° F dew point

- Flow capacities of 0.1 SCFM to 3.2 SCFM

- Efficient drying at pressures of 30 PSIG to 120 PSIG

- Miniature design requires minimal space in OEM equipment

- Install at point-of-use or use with fractional horsepower air compressors

- Precision orifices to control purge

- solid-state timer with memory for accurate cycling

- Non-plugging and non-corroding purge mufflers

- Power consumption is 6 watts or less

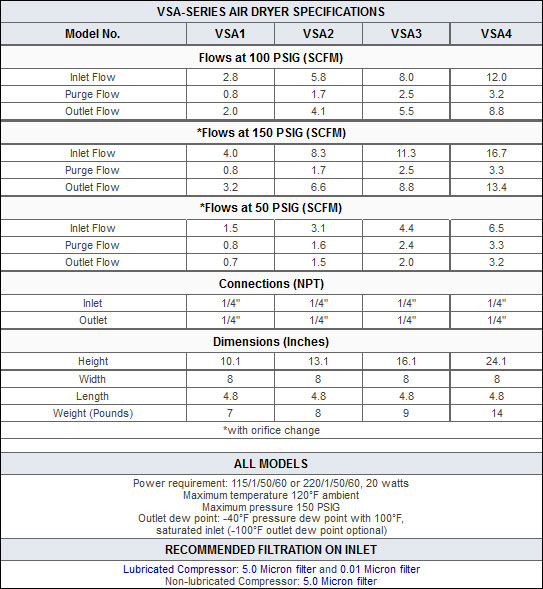

VSA-Series Desiccant Air Dryers capacity from 2.8 to 12 SCFM

The VSA miniature heatless air dryer uses pressure swing adsorption (PSA) to produce low dependable dewpoints of -40°F or -100°F. It is a basic, economical unit. The VSA will provide years of trouble free service at a most reasonable price for your facilities or original equipment you manufacture (OEM).

- Features

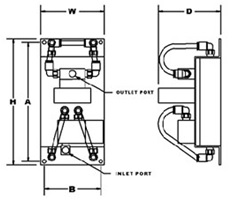

- Specifications

- Dimensions

- Brochure

- 6″, 9″, 12″, and 20″ Desiccant Chambers

- Flows to 12 SCFM

- Max Pressure 150 PSIG

- Compact and lightweight aluminum construction

- solid-state timer with built-in memory

- NEMA 1 Electricals

- 1 minute purge cycle

- Fixed orifice purge control

- Two inlet and two outlet ports for ease of installation

- Standard non-plugging and non-corroding purge mufflers