The Aircel Off Shore E-Series is a fully automatic Dual Tower Heatless Regenerative Compressed Air Dryer with an integrated Energy Management Purge Reduction System. The Offshore series has all the energy saving features of the AHLD-E series plus corrosion resistance. The paint is upgraded to a corrosion resistant UV resistant industrial coating that has a field proven long field life. In addition no yellow metals are present eliminating easily corroded materials.

Delivering Energy Efficient & Purge Reduction Control The Aircel Programmable Controller (APC) and Energy Management System (EMS) is standard on the AHLD. This energy-saving demand cycle reduces purge air and optimizes dryer performance by monitoring the moisture fast and early in the middle portion of the tower desiccant bed. This control panel automatically adjusts the regeneration cycle maintaining dew point and extending the drying cycle. Switching is less frequent, reducing dryer maintenance and fully utilizing desiccant capacity. This addition will improve reliability and performance while sustaining a constant dew point. The end result is an overall purge reduction and significant energy savings

Features

|

Additional Standard Features • Remote start/stop control • Fail-safe design flow design • Stainless steel desiccant supports and air diffusers • Counter-current regeneration • High performance butterfly valves (≥ 1000 scfm models) • Easy installation with single point connection for electrical • Adjustable (5 & 10 min.) NEMA cycle • Corrosion resistant • SS control air tubing • No yellow metals

• All-pneumatic control package (no electricity required) • Pre-piped filters and by-pass valve packages • High inlet pressure up to 7000 psig • -100°F pressure dew point • NEMA 7 Optional Controller Features • Failure-to-shift alarm • High-inlet temperature alarm • Dew point monitor • Pressure alarm • Visual moisture indicator • Optional communications: |

|

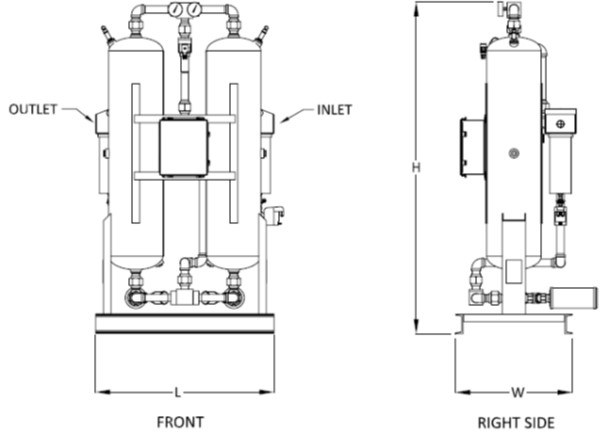

| Model | Capacity SCFM | Connection | H" | L" | W" | Weight lbs. |  |

| AHLD-70 E | 70 | 3/4” NPT | 73 | 26 | 22 | 410 | |

| AHLD-100 E | 100 | 1” NPT | 75 | 30 | 24 | 490 | |

| AHLD-150 E | 150 | 1” NPT | 75 | 30 | 24 | 560 | |

| AHLD-200 E | 200 | 1-1/2” NPT | 85 | 34 | 24 | 800 | |

| AHLD-250 E | 250 | 1-1/2” NPT | 85 | 34 | 24 | 870 | |

| AHLD-300 E | 300 | 1-1/2” NPT | 86 | 46 | 30 | 990 | |

| AHLD-350 E | 350 | 2” NPT | 87 | 46 | 30 | 1020 | |

| AHLD-450 E | 450 | 2” NPT | 87 | 46 | 30 | 1140 | |

| AHLD-500 E | 500 | 2” NPT | 89 | 50 | 30 | 1250 | |

| AHLD-600 E | 600 | 2” NPT | 89 | 50 | 30 | 1450 | |

| AHLD-750 E | 750 | 2” NPT | 90 | 50 | 30 | 1850 | |

| AHLD-1000 E | 1000 | 3” FLG | 94 | 66 | 40 | 2800 | |

| AHLD-1250 E | 1250 | 3” FLG | 98 | 70 | 40 | 4000 | |

| AHLD-1500 E | 1500 | 3” FLG | 99 | 70 | 40 | 4600 | |

| AHLD-2000 E | 2000 | 4” FLG | 109 | 82 | 50 | 5800 | |

| AHLD-2500 E | 2500 | CF | |||||

| AHLD-3000 E | 3000 | CF | |||||

| AHLD-3500 E | 3500 | CF | |||||

| AHLD-4000 E | 4000 | CF | |||||

| AHLD-4500 E | 4500 | CF | |||||

| AHLD-5000 E | 5000 | CF |