Externally Heated Regenerative Desiccant Dryer

The Aircel AEHD (150 – 3,000 scfm) Externally Heated Desiccant Compressed Air Dryer is a fully automatic, PLC controlled, self-contained unit offering a fail-safe design – in the event of power interruption and/or air loss, the purge exhaust valves close preventing damage to the dryer and the process. The combination of 1) high moisture capacity, premium grade, high crush strength activated alumina used in 2) optimally sized ASME code desiccant towers providing low velocity and high contact time through the adsorbent beds delivers long service life and consistent performance.

All Aircel dryers are designed to give our customers the best value available in the industry – reliable performance to CAGI ADF 200 specification while consuming the lowest amount of energy possible.

The Aircel AEHD Series Dryers (150 – 3,000 scfm) utilize process air for regeneration of the desiccant bed similar to the heatless designs. However, this expanded process air is heated prior to entering the off-line bed, significantly reducing the required consumption and the cost of operation. Additionally process air is consumed during depressurization of the offline desiccant tower. In total these functions amount to an average process air use of 7% of the rated capacity of the dryer.

- Features & Benefits

- How it Works

- Brochure

- Removable, stainless steel desiccant bed support screens.

- Tower pressure gauges.

- ASME code desiccant towers (6” vessels and larger).

- High temperature outlet check valves.

- Fail-safe design.

- 1-1/2” thick fiberglass insulation.

- Highly reliable programmable logic control (PLC).

- Energy saving venturi option available on request.

AEHD SERIES Model Comparison

|

Model |

Capacity1(scfm) |

Connection (inches FNPT/ANSI) |

Heater kW |

FullLoad Amps |

Voltage (Standard) |

Dimensions (inches) |

Pressuremax. (psig) |

Weight (lbs) |

Desiccant Both Vessels (lbs) |

||

|

Height |

Width |

Depth |

|||||||||

|

AEHD-150 |

150 |

1 |

2.5 |

3.2 |

460V/60 Hz/3Ph |

75 |

45 |

30 |

150 |

810 |

200 |

|

AEHD-250 |

250 |

1-1/2 |

4.5 |

6.2 |

460V/60 Hz/3Ph |

75 |

50 |

35 |

150 |

1200 |

400 |

|

AEHD-350 |

350 |

2 |

6 |

8.1 |

460V/60 Hz/3Ph |

75 |

54 |

35 |

150 |

1600 |

500 |

|

AEHD-500 |

500 |

2 |

9 |

11.8 |

460V/60 Hz/3Ph |

83 |

60 |

39 |

150 |

2000 |

700 |

|

AEHD-750 |

750 |

3 FLG |

12 |

15.6 |

460V/60 Hz/3Ph |

89 |

75 |

44 |

150 |

2600 |

960 |

|

AEHD-1000 |

1000 |

3 FLG |

15 |

19.3 |

460V/60 Hz/3Ph |

98 |

88 |

54 |

150 |

3500 |

1400 |

|

AEHD-1200 |

1200 |

3 FLG |

20 |

25.6 |

460V/60 Hz/3Ph |

109 |

96 |

60 |

150 |

3900 |

1800 |

|

AEHD-1500 |

1500 |

4 FLG |

24 |

30.6 |

460V/60 Hz/3Ph |

109 |

102 |

69 |

150 |

4500 |

2100 |

|

AEHD-2000 |

2000 |

4 FLG |

30 |

38.2 |

460V/60 Hz/3Ph |

115 |

120 |

69 |

150 |

5800 |

2800 |

|

AEHD-2500 |

2500 |

4 FLG |

36 |

45.7 |

460V/60 Hz/3Ph |

115 |

130 |

73 |

150 |

6600 |

3600 |

|

AEHD-3000 |

3000 |

6 FLG |

45 |

57.00 |

460V/60 Hz/3Ph |

120 |

140 |

77 |

150 |

7500 |

4200 |

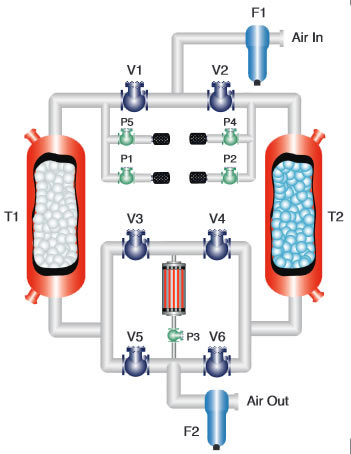

Filtering and drying incoming air. Hot, saturated compressed air is filtered as it passes through our 0.01 micron high-efficiency coalescing prefilter (F1, recommended option) before entering the dryer. Compressed air continues through the inlet valve (V1), is dried in the desiccant tower (T1), and exits through an outlet valve (V5) and final particulate filter (F2, recommended option), while the other desiccant tower (T2) is being regenerated.

Desiccant regenerated in T2. A portion of the dried air is diverted through purge valve (P3) at near atmospheric pressure and heated by the electric heater (or optional steam heater) to 400°F before passing through regeneration valve (V4) and into the regeneration tower (T2).

The heated air removes moisture vapor from the desiccant surface.

Dryer operation is performed automatically by a programmable logic controller (PLC). The standard drying and regeneration time cycle is 8 hours. While one tower is drying incoming compressed air for 4 hours, the other tower is regenerating for 3 hours (heating time), then cooling for 50 minutes, and finally repressurizing to the line pressure for 10 minutes before switching over to the other tower. Switching from one tower to the other is performed only when both desiccant towers are at line pressure to prevent line surge and to minimize desiccant abrasion.