Coalescing Pipeline Filter Multiple Stage – Shawndra Series R100™

Shawndra™ Products has developed a new coalescing pipeline filter product (patent pending). This new R100™ series filter is a horizontal pipeline filter with extended surface area vertical elements. Element service life has been extended tenfold and more. Complete service can be accomplished with a single 3/4” adjustable wrench in less than 1.5 hours. Design pressures to 3000 psig std.

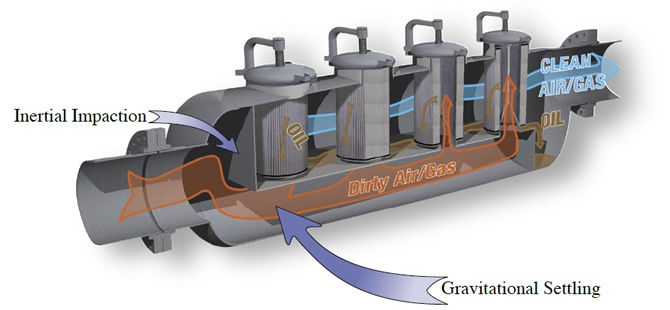

R-Series coalescing pipeline filters remove the solid particles and liquids from natural gas, vastly reducing or eliminating service to engines, turbines and other compressors, valves and meters. Superior filtration is achieved first through inertial impaction, secondly through gravitational settling, and thirdly through a nearly vertical coalescing multi-stage filter element with efficiencies of 0.03 micron and higher. Media has been independently lab tested using various oils such as contaminan.

These coalescing filter-separators use dry type replaceable coalescer elements. They provide safe and efficient operation, convenient access, and exceptional service life. Their large rugged filter elements have pleated media to combine high efficiency with low ΔP.

Engineered for horizontal installation, vertically oriented coalescing filter elements, and integral Slug Catcher. Angled element base support enhances fluid drainage. Quick opening closures and alternate element stacks are available.

Solid particles and free liquids removed from nat. gas streams prevents damage to rotating turbine blades and other equipment in the fuel supply.

A Field Proven Coalescing Pipeline Filter Design

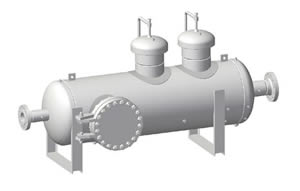

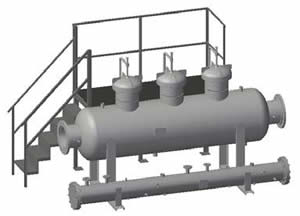

The largest natural gas supplier in the Appalachian basin recently installed Sparks TM R100™ coalescing pipeline filters at five coal bed methane operations in Virginia and West Virginia. The first two of these filter units have now been in continuous, service-free operation for six months and more. One unit (See image above) processes seven million cubic feet per day of natural gas, filtered at the manifold head of ten gas wells, to remove water, liquid mist, coal dust, and sand to protect two downstream Caterpillar engines and two compressors. R-Series filters remove the solid particles and liquids from natural gas, utilizing multi stage filtration technology vastly reducing maintenance service and downtime to compressors, engines , turbines and other gas fired equipment.

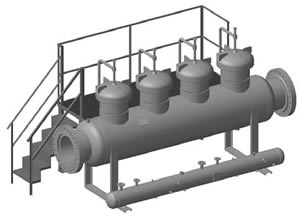

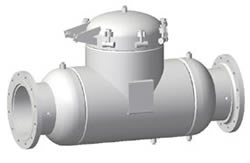

This same coalescing pipeline filter (See image above) replaced a competitive unit (See image above) that required seven 4” x 36” elements. The new Sparks Series R100 filter with only three elements had operated continuously for six months without needing any service saving this CBM producer seventy-five hours of remote field maintenance and over $20,000 in replacement filter elements.

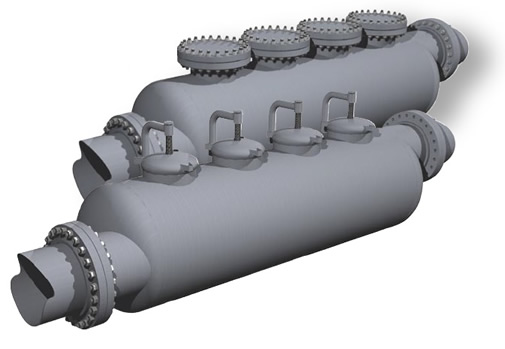

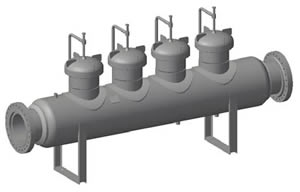

Coalescing Pipeline Filter R100™ Multiple Stack Options for high pressure/high flows

All units ASME U stamp with National Board Registration

Options for the Series 100 Coalescing Pipeline Filters include:

- Relief Valves

- Dump Valves

- Float Valves

- Sight Glass

- Ladders/Platform

- Assorted gages & piping

- Pads of mesh or directional separators

- One, Two, Three or Four stage high flow elements available

Overall Dimensions:

- Length: 150”

- Width: 54”

- Height: 78”

Overall Dimensions:

- Length: 218”

- Width: 42”

- Height: 108”

Overall Dimensions:

- Length: 178”

- Width: 93”

- Height: 104”

Overall Dimensions:

- Length: 214”

- Width: 93”

- Height: 108”

- 2 Chamber sump tank

Quick opening O-ring closure

Adjustable legs available

R100™ Mini

Low pressure bolted closure

Connection sizes 6” & smaller

(Eliminates the need for (3) vessels in gas piping meter runs

Why you should buy R-Series coalescing pipeline filters from AVP

- AVP has over 45 combined years of experience in natural gas dehydration applications

- AVP can answer questions and quote prices quickly, same day in most cases

- Call 866.660.0208 today or chat with us right now!