Altec AIR’s HHP Series High Pressure Heatless Desiccant Air Dryers are specially designed for higher pressure applications.

They are available in three specific designs rated for maximum working pressures of 250, 500, and 1000 PSIG.

- ISO 8573.1 Class 2 -40°F/C Standard Outlet Dewpoint

- Factory installed Filters w/ Differential Pressure Gauges and Pre-Filter Timer Drain

- Separate Re-Pressurization Circuit (HHP-0100 & Larger)

- Feature Rich ETL Listed Pro-Logic Controller w/ NEMA 4 Enclosure

- Regulated Control Air & Adjustable Purge

Standard Features:

- Power Requirements - 120 VAC, 1 Phase, 60 Hz

- Maximum Pressure -

- 250 PSIG (HHP-0250-0025 - HHP-0250-1000)

- 500 PSIG (HHP-0500-0050 - HHP-0500-1400)

- 1000 PSIG (HHP-1000-0075 - HHP-1000-1800)

- Maximum Operating Temperature - 120°F / 49°C

- ASME / CRN Approved Safety Relief Valves

Optional Features:

- EcoTronic Dew Point Demand Control

- Bypass Packages

|

|

General Specifications & Dimensions:

|

|

INLET Flow SCFM

|

Maximum Allowable Working Pressure (MAWP) PSIG

|

Inlet/Outlet Ports (NPT)

|

|

HHP-0250-0025-1

|

25

|

250

|

1/2"

|

|

HHP-0250-0055-1

|

55

|

|

HHP-0250-0140-1

|

140

|

1"

|

|

HHP-0250-0250-1

|

250

|

|

HHP-0250-0390-1

|

390

|

1-1/2"

|

|

HHP-0250-0570-1

|

570

|

|

HHP-0250-1000-1

|

1000

|

2"

|

|

|

|

HHP-0500-0050-1

|

50

|

500

|

1/2"

|

|

HHP-0500-0095-1

|

95

|

|

HHP-0500-0200-1

|

200

|

1"

|

|

HHP-0500-0350-1

|

350

|

|

HHP-0500-0550-1

|

550

|

1-1/2"

|

|

HHP-0500-0800-1

|

800

|

|

HHP-0500-1400-1

|

1400

|

2"

|

|

|

|

HHP-1000-0075-1

|

75

|

1000

|

1/2"

|

|

HHP-1000-0130-1

|

130

|

|

HHP-1000-0250-1

|

250

|

1"

|

|

HHP-1000-0400-1

|

400

|

|

HHP-1000-0750-1

|

750

|

1-1/2"

|

|

HHP-1000-1000-1

|

1000

|

|

HHP-1000-1800-1

|

1800

|

2"

|

|

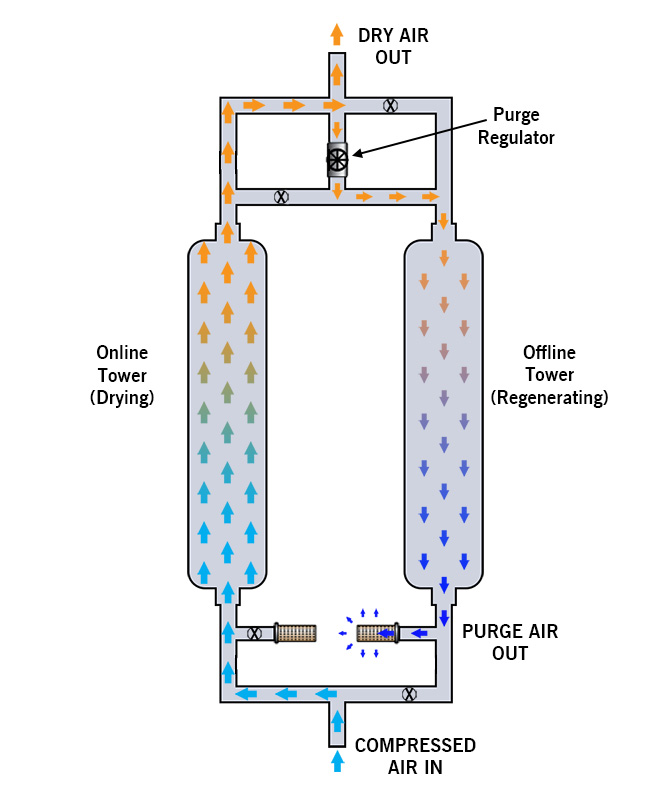

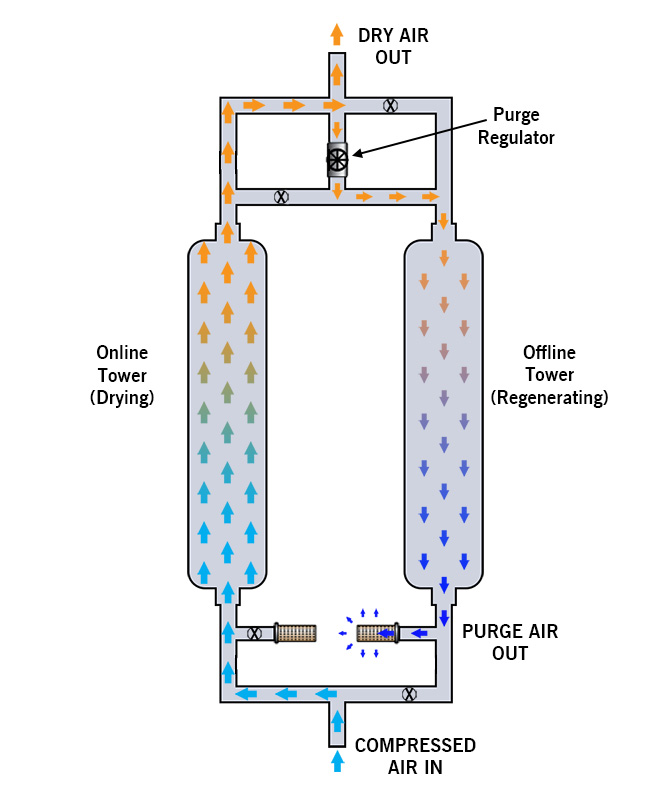

HHP Series Drying Process

Compressed air, saturated with water vapor, flows upward through the Online (Drying) Tower. The water molecules adhere to the porous surface of the Desiccant, where the residual water content of the compressed air is lowered to a Pressure Dew Point (PDP) of -40°F or lower. Concurrently, some of this dry air is directed downward through the depressurized Offline Tower in a process referred to as Regeneration. This dry air sweep desorbs water molecules from the surface of the Desiccant and is exhausted to atmosphere, preparing that Tower for its next Online cycle. This process is known as Pressure Swing Adsorption (PSA) and is typically completed in a fixed 10-minute NEMA cycle, with the Towers alternating between Drying & Regenerating, typically every 5 minutes.

|

|