Why CO2 Adsorbers Are Essential in Precision-Drive…

Posted by AVP on Dec 24th 2025

CO₂ isn’t always the first gas researchers worry about—but in many laboratory settings, even trace levels can distort results, skew baselines, or impact the performance of sensitive analytical instruments. That’s why it’s critical to include CO2 adsorbers in your compressed air system, especially in university labs where precision is everything.

Whether you’re running a gas chromatograph, a TOC analyzer, or any sensitive environmental testing equipment, having a clean, dry, CO₂-free air supply isn’t just ideal—it’s essential.

What CO₂ Adsorbers Do in Laboratory Applications

Unlike standard air dryers, CO₂ adsorbers are designed to remove both carbon dioxide and moisture from compressed air in one integrated system. These units typically operate using 13X molecular sieve media inside dual-tower, pressure swing adsorption designs. While one tower is active in adsorbing contaminants, the other regenerates—ensuring continuous delivery of dry, CO₂-free air.

We offer a range of CO2 adsorbers built to meet the demands of university labs, analytical research facilities, and environmental monitoring operations. With flow rates ranging from 0.06 SCFM to 6.37 SCFM, there’s a solution for everything from a single lab bench to full multi-instrument setups.

Featured Product: CAS4-11 CO₂ Adsorber-Dryer

One standout option is the CAS4-11 CO₂ Adsorber-Dryer, engineered for high-performance environments where air purity directly impacts results. It offers:

- Outlet CO₂ concentration: less than 1 ppm

- Dew point performance: down to -100°F atmospheric

- Outlet flow rate: 6.37 SCFM

- Operating pressure range: 50–150 PSIG

- Quiet, compact design with easy installation and low energy consumption (115 VAC, 6 watts)

- Continuous self-regeneration, no manual switching

This unit is ideal for research labs using sensitive instruments that require consistently clean, dry air. Since it handles both CO₂ and moisture removal, there’s no need for a separate air dryer. It’s a single-system solution that simplifies your setup while improving reliability.

What a -100°F Dew Point Means for Sensitive Laboratory Tests

A -100°F atmospheric dew point indicates extremely dry air—we’re talking less than 1 part per million (ppm) of water vapor in the air. In lab applications, where even tiny amounts of moisture can compromise data, damage instruments, or interfere with chemical reactions, this level of dryness is crucial.

- In FTIR and other optical instruments, water vapor absorbs in the same infrared regions as many analytes—especially around 1600 cm⁻¹ and 3400 cm⁻¹.

- GC detectors, especially FID and TCD, are sensitive to water vapor in the carrier gas or air supply.

- TOC analyzers are used to detect organic carbon in water. Moisture in the compressed air used for oxidation or carrier gas can affect combustion temperature and flow consistency.

- In moisture-sensitive components like pneumatic actuators, valves, sensors, and optics, even slight condensation can lead to corrosion, clogging, or erratic behavior.

- Perhaps the most underrated benefit—a consistently low dew point removes moisture as a variable in troubleshooting.

Why CO₂-Free Air Matters in Academic Labs

Many research facilities and universities rely on TOC analyzers, gas chromatographs, FTIR spectrometers, and other precision-driven tools. These instruments often measure carbon-based compounds or require stable baselines—meaning ambient levels of CO₂ (usually around 375 ppm) can interfere with accuracy.

- Even small fluctuations in air quality can cause issues:

- Baseline drift in spectroscopy

- Measurement noise in gas analysis

- Unexpected spikes in TOC readings

By using a CO₂ adsorber that also functions as a dryer, labs eliminate two major threats—moisture and carbon dioxide—with one efficient, compact system.

When You Only Need Moisture Removal—Not CO₂ Control

That said, not every lab needs CO₂ removal. For some setups—particularly in teaching labs, light-duty workstations, or OEM systems—moisture is the only major concern. In those cases, a full CO₂ adsorber may be unnecessary.

For applications like these, the MDH Series regenerative desiccant dryers offer a targeted solution for delivering dry compressed air in a smaller footprint. These units are designed to:

- Achieve dew points as low as -100°F

- Operate at pressures from 30 PSIG to 120 PSIG

- Run on low power (6 watts or less)

- Fit within OEM equipment cabinets or small benchtop setups

One example is the MDH3-AHE Mini Regenerative Desiccant Dryer, which offers:

- Outlet flow: 0.83 SCFM at 100 PSIG

- Optional -100°F dew point

- Compact form factor: just 8.8" H x 4" W

- Reliable cycling via solid-state timer

- Quiet operation with non-plugging purge mufflers

These dryers are ideal when CO₂ isn’t a concern but ultra-dry air is still necessary—particularly for instrument protection, peak resolution in chromatography, or basic moisture-sensitive testing.

Choosing the Right Solution for Your Lab

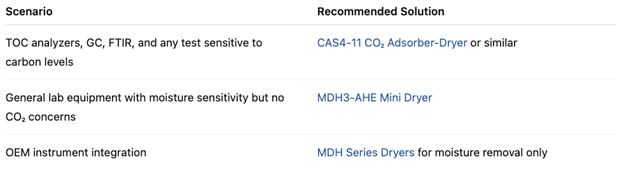

The key is understanding your specific air quality needs. Here's a quick breakdown:

For labs where both CO₂ and moisture interfere with results, CO2 adsorbers are the most efficient and technically sound choice. For simpler setups or lower-sensitivity applications, a miniature desiccant dryer may be all you need.

Clean Air, Clear Data

Compressed air isn’t just a utility in a laboratory setting—it’s a variable that can affect your entire workflow. Selecting the right air treatment solution is one of the most impactful decisions lab managers and researchers can make to ensure consistency, accuracy, and equipment longevity.

At Air Vacuum & Process Inc., we offer both full-spectrum CO₂ adsorber-dryers and point-of-use mini air dryers, so you can match the right solution to your lab’s specific demands.

Explore our complete lineup of CO2 adsorbers or browse miniature desiccant dryers for moisture-only needs. Whether you need precision at scale or efficient drying in tight spaces, we’ll help you breathe easier—literally and analytically.