Solenoid Electric Drain EDV-115

The inexpensive and reliable Terminator electric automatic drain valve automatically removes condensate from your air system. It has an integral strainer to prevent clogging and saves time and money by eliminating the need for manual draining. The Terminator automatic drain valve also eliminates the need for the wasteful practice of bleeding, or leaving cracked open manual drain valves.

- Features & Benefits

- Applications

- Brochure

- Adjustable cycles Open setting 1 – 60 seconds Closed setting 1 – 60 minutes

- Compact and light weight, less than 2 pounds

- Outlet hose barb connection for drain lines

- Integral strainer

- Inlet isolation valve for easy servicing

- Solid state timer

- Indoor or outdoor installation

- NEMA 4 Lexan enclosure

- Power on and valve open status LEDs

- Override test function to test valve open time setting

- 300 PSIG pressure rating

- 115V, 220V, or 12V DC

- Filters

- Drop legs

- Receivers

- Separators

- After-coolers

- Refrigerated dryers

Motorized Drain Valves

Whether you need the simplicity of a basic valve or the flexibility of added features, the Sentinel Series is your solution. Choose from two models, plus different options and accessories to fit the level of adjustment and controls you need.

For the most dependable draining, install the Van Air Sentinel Series motorized ball valve. The Sentinel’s heavy-duty ball valve can manage virtually any fluid in a wide variety of applications. Depend on it for nearly any fluid service.

MDV-400I

For dependable draining at consistent intervals choose Sentinel model MDV-400I. A power-on LED and test button are conveniently located on the top cover. To reset the valve, simply adjust the switches on the internal circuit board. Adjustable intervals between valve actuations are 30 minutes to 30 hours. Adjustable draining periods are 5, 10, 15 and 20 seconds.

MDV-400L

If you prefer an easy-to-use keypad for convenient cycle timing adjustments and a handy LCD cycle status readout, choose Sentinel model MDV-400L. You’ll never wonder when it’s set to actuate again with its continuous, clear countdown display of remaining cycle or drain open times. Added features include an external test and valve fault functions, both with LCD readout. Adjustable intervals between valve actuations are 1 minute to 99 hours 59 minutes. Adjustable draining periods are 1 second to 99 minutes 59 seconds.

- Features & Benefits

- Applications

- Brochure

- 115 VAC, 230 VAC, 12 VDC, 24 VDC

- 10′ power cord

- Two-piece brass ball valve

- ½”, ¾”, or 1″ NPT connection

- Thermoplastic top cover

- Epoxy powder-coated metal base

- NEMA 4 enclosure

- 0°F – 120°F ambient temperature range

- Optional stainless steel valve (standard brass)

- Optional alarm contact for remote indication of fault mode

- Optional high/low liquid level sensor, flood level switch for zero air loss operation

- Brass valves with NPT connection sizes: ½”, ¾”, 1″, 1 ½”, 2″, 2 ½”, 3″

- Stainless steel valves with NPT connection sizes: ½”, ¾”, 1″, 1 ½”, 2″

- Cooling towers

- Process tanks

- Separators

- Compressed air filters

- Compressed air receiver tanks

- Compressed air dryers

ROBO-Drain Pneumatic Zero-Loss Drain Valves

The Robo Drain RD Series Drain Valve is a versatile draining system ideal for receivers, dryers, tanks, drop legs, pipes, and any equipment requiring regular condensate removal. With no electricity required for operation, the pneumatically operated RD Series automatic drain valve is well suited for remote or portable applications and is safe to operate in any hazardous area.

As a demand-operated drain, the RD Series Drain Valve automatically does the work of draining for you, eliminating the guesswork of setting the cycle time of the timed drain valve. As condensate levels change, the RD Series automatic drain valve automatically adjusts to drain as needed, without permitting valuable compressed air to escape.

Designed with a full flow ball valve and proprietary pilot valve using a magnet and proximity switch, the RD Series Drain Valve will not clog. This unique pilot valve design allows the control air to be totally separated from the condensate, preventing any attraction of pipe scale. The ball valve eliminates the need to install a strainer. This means better dependability than competitive units.

The see-through vessel allows visual inspection of the condensate. The test button, which is included on both the brass and stainless steel units, make it easy to check valve operation or manually drain the system. There are many versions available in our online store, vertical & horizontal units, extra sump capacity, all stainless steel, high-pressure design and valves for vacuum service. Just visit our store through the “buy now” button

- Features & Benefits

- Applications

- Brochure

- No electricity needed

- Zero air loss saves energy

- Full flow ball valve for reliable operation

- Visible liquid level verifies performance

- Safe operation in hazardous areas

- Manual override is standard

- Receiver tanks

- Compressed air dryers

- Coalescing filters

- Drop legs

- Condensate collection points

- Remote or portable equipment where no power is available

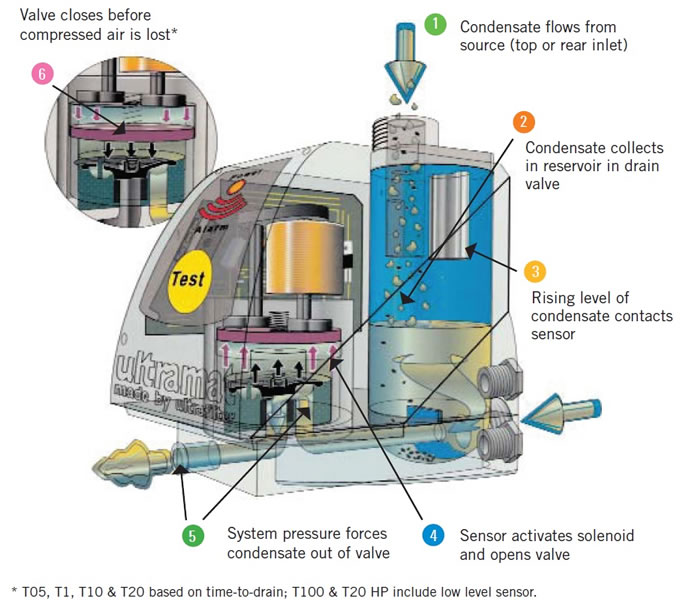

Zero-Loss Drain Valve

Aircel Ultramat UFM-T zero air-loss condensate drain valve has a compact design allowing for installation in restricted space applications. The UFM-T is designed to open only when necessary and close before any loss of compressed air can occur. The unique internal reservoir and flow channels reduce the possibility of blockage and minimize fouling of the drain valve seat allowing more thorough processing at a downstream oil/water separator.

Optimization of compressed air systems can provide energy efficiency improvements of 20 to 50 percent. One contributor to the inefficient use of compressed air, which can increase cost, is the condensate drain. Liquid condensate, which naturally accumulates in various spots within a compressed air system, must be drained frequently or serious consequences can adversely impact downstream hardware, finished products and the compressed air system itself.

Typical drains that operate on a timer allow compressed air to vent from the systems with every cycle. Timer operated drains will open regardless of how much, or how little, condensate has collected between cycles. In addition, float drains are subject to fouling and allow compressed air to bleed out of the system even when the float is resting in its seat.

- Features

- Benefits

- Models

- Applications

- How it Works

- Brochure

- Design of internal reservoir and flow channel minimizes emulsification of condensate, allowing for more thorough processing at downstream oil/water separator.

- Rigid corrosion-resistant housing made from glass fiber reinforced plastic structure.

- All metal parts coated; gaskets and diaphragm material is Viton®.

- External alarm contacts (excluding T05 drain).

- Easily accessible push-to-test button.

- Electronically controlled and self-monitored for operation faults.

- Condensate inlet can be from the top or from the rear.

- Preinstalled power cord (UFM-T05 through UFM-T20).

- 24 or 110V – 230 V AC power supply without additional transformers.

- Design minimizes fouling of valve seat.

- Compact design allows installation in restricted spaces.

- Ergonomic design with rounded, clearly visible control panel.

- Silent operation.

- Condensate level sensor requires no moving parts.

- Pays for itself in less than six months.

Ultramat zero air-loss, electronically controlled condensate drains are at many points to ensure condensate drainage without compressed air-loss.

- On the compressor itself

- On compressor aftercoolers

- On accumulator/surge tanks

- On coarse coalescing prefilters before refrigerated and desiccant dryers

- On fine coalescing prefilters before refrigerated and desiccant dryers

- On refrigerated dryer cold-points or outlets